There aren’t many home appliances as vital and depended upon as the washing machines. Our daily routines remain smooth and continuous due to its significance of efficiency, durability, and simplicity of maintenance. In this context, GE washing machines stand out as a beacon of quality in the vast sea of household appliances. In this blog post, we will explore the inner workings of GE washing machines, the variety of parts they are composed of, and why choosing the right components matters in ensuring the longevity and efficiency of your machine. Prepare to delve into the world of GE, where sophistication meets utility, ensuring your garments are in the best of hands.

Table of Contents

Understanding the GE Washing Machine: An Overview of Its Design

GE’s Approach to Washing Machine Engineering

Known for their innovative spirit and commitment to building appliances that consumers can rely on, GE’s washing machines are a testament to the company’s design philosophy. GE appliances are engineered with the intent of creating a user-friendly experience, incorporating advanced technology, and promoting long-term reliability.

The Anatomy of a GE Washer

Every GE washing machine is an amalgam of numerous parts and components, each performing a specific role in the washing process. From the water inlet valves that control the flow of water into the machine to the motor and the drum where your clothes are actually washed, the synergy between these parts is what makes a GE washer function effectively.

You May Also Like: Who Makes Hisense Refrigerators?

Critical Components of a GE Washing Machine

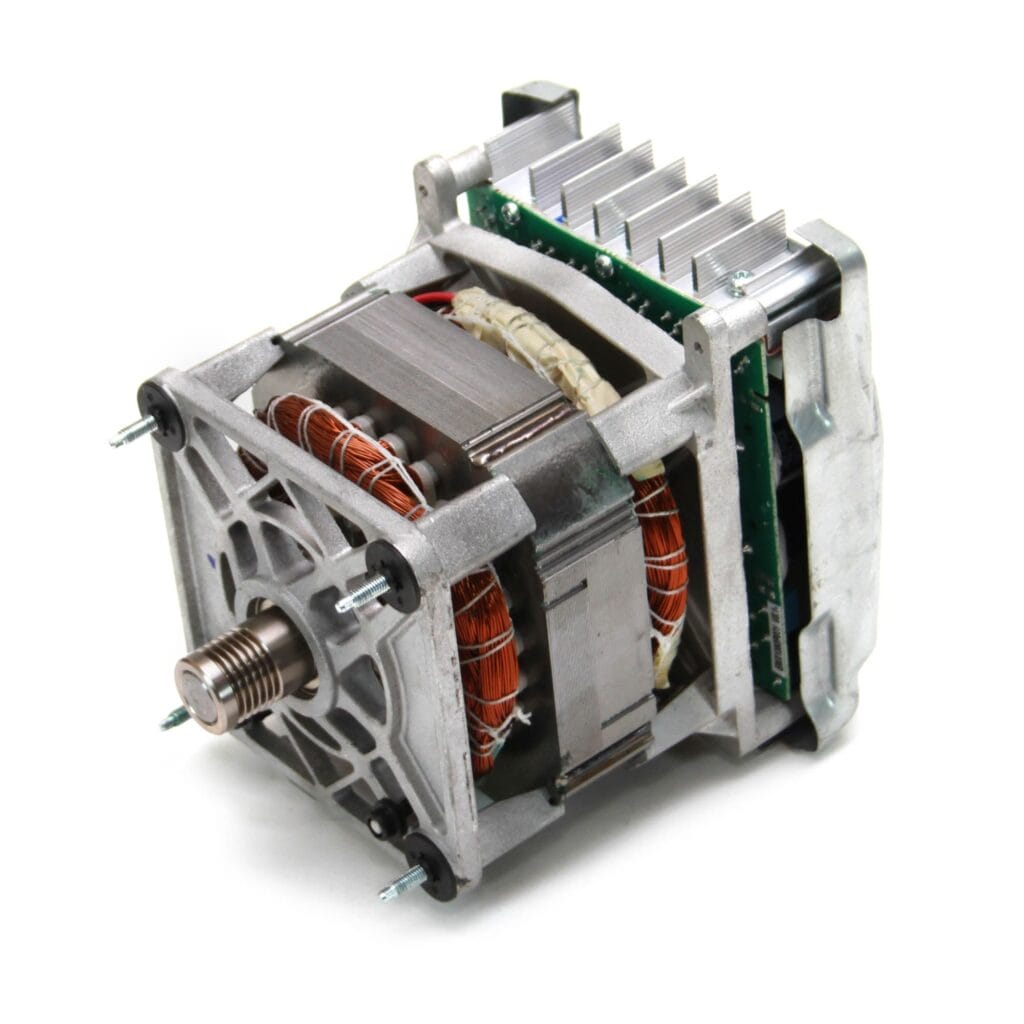

The Motor: Heart of the GE Washing Machine

GE washing machines are known for their durability and reliability. The Motor is also known a heart of any machine. The motor is responsible for spinning the tub and agitator, which cleans your clothes.

There are two main types of motors used in GE washing machines:

Direct drive motors: These motors are directly connected to the tub and agitator. They are the most common type of motor used in GE washing machines.

Belt drive motors: These motors are connected to the tub and agitator by a belt. They are less common than direct drive motors, but they are still used in some GE washing machines.

Direct drive motors are more efficient than belt drive motors. They are also more quieter and durable.

Belt drive motors are less expensive than direct drive motors. They are much easier to repair. However, they are not efficient or durable like direct drive motors.

How to tell if your GE washing machine motor is bad

There are a few signs that your GE washing machine motor may be bad. These signs include:

- The washing machine is making a loud noise.

- The washing machine is not spinning properly.

- The washing machine is not agitating properly.

- If you are experiencing any of these signs, you should have your GE washing machine serviced by a qualified technician.

How to prolong the life of your GE washing machine motor

There are a few things you can do to prolong the life of your GE washing machine motor:

- Do not overload the washing machine.

- Use the correct cycle for the type of laundry you are washing.

- Clean the lint trap after each use.

- Have your washing machine serviced regularly.

- By following these tips, you can help to ensure that your GE washing machine motor will last for years to come.

Water Inlet Valve: The Gateway for Water Supply in GE Washing Machine

GE washing machines are known for their reliability and performance, and the water inlet valve plays major role in ensuring smooth operation. This essential component controls the flow of water into the washing machine, regulate the amount and time of water intake for each wash cycle.

Understanding the Water Inlet Valve

The water inlet valve mostly found on the back side of the washing machine which is connected with water supply lines. The valve is made up of an electromagnetic solenoid to control water flow by opening and closing the valve. The washing cycle starts, the machine pass an electronic signal to solenoid and the solenoid opens valve to allow water to enter in the machine.

Signs of a Faulty Water Inlet Valve

Several signs indicate that your GE washing machine’s water inlet valve may be malfunctioning:

- Water Leaks: Leaks around the water inlet valve or hoses are a common sign of a faulty valve.

- Water Flow Issues: If the water flow is inconsistent, too slow, or too fast, the valve may be malfunctioning.

- Unusual Water Usage: If your washing machine is using significantly more or less water than usual, it could indicate a valve issue.

- Strange Noises: If you hear unusual noises, such as clicking or buzzing, coming from the water inlet area, it could be a sign of a faulty valve.

Troubleshooting and Replacement of Water Inlet Valve

If you suspect a problem with your water inlet valve, it’s essential to take action promptly to prevent water damage and ensure efficient washing machine operation.

- Turn Off Water Supply: Before attempting any troubleshooting, turn off the water supply to the washing machine.

- Inspect the Valve and Hoses: Check the water inlet valve and hoses for leaks, cracks, or damage. Replace any damaged components.

- Clean the Filter: If the filter screen on the water inlet valve is clogged, it can restrict water flow. Clean the filter thoroughly and reinstall it.

- Test the Solenoid: Using a multimeter, check the continuity of the solenoid. If it’s faulty, you’ll need to replace the water inlet valve assembly.

- Seek Professional Help: If you’re not comfortable troubleshooting the water inlet valve yourself, contact a qualified appliance repair technician.

Prevention and Maintenance of Water Inlet Valve

To prolong the life of your GE washing machine’s water inlet valve and prevent future issues:

- Regular Cleaning: Clean the filter screen on the water inlet valve regularly to remove debris and prevent clogs.

- Gentle Hoses: Avoid kinking or bending the water hoses, as this can damage them over time.

- Proper Use: Use the washing machine according to the manufacturer’s instructions and avoid overloading it.

- Regular Maintenance: Schedule regular appliance maintenance checks to ensure all components are functioning correctly.

A well-maintained water inlet valve ensures that your GE washing machine operates smoothly, efficiently, and without water leaks or issues. By understanding the valve’s function, identifying signs of trouble, and taking preventive measures, you can keep your washing machine in top condition for years to come

The Agitator or Wash Plate: GE Washing Machine Movement-Makers

The heartbeat of any washing machine lies in its agitator or wash plate. Depending on the model of the GE washer, it may use an agitator or a wash plate to move the clothes through the water. These components play a pivotal role in determining the efficiency and effectiveness of your laundry process. Let’s take a journey through the evolution of washing machines and explore the choices presented by GE.

Understanding Agitators

Traditionally, agitators have been the go-to choice for many washing machine manufacturers, including GE. These components are designed to create a dynamic washing environment by agitating the water and clothes. While effective, agitators have their drawbacks, such as potential wear and tear on fabrics and higher energy consumption.

The Rise of Wash Plates

Wash plates, on the other hand, represent a newer technology that aims to address the limitations of agitators. They operate with a gentler motion, resulting in less stress on clothes. This alternative design has garnered attention for its efficiency and reduced environmental impact.

Performance Comparison

When it comes to cleaning performance, the battle between agitators and wash plates is fierce. Analyzing factors such as stain removal, water usage, and energy efficiency can help consumers make a choice that suits their lifestyle and values.

User Preferences

Consumer preferences play a crucial role in the ongoing debate. Some users swear by the effectiveness of agitators, appreciating their robust cleaning power, while others lean towards the gentler approach of wash plates. Understanding individual preferences is key to making the right choice.

Maintenance and Durability

Maintaining your washing machine is essential for its longevity. Agitators may require different care compared to wash plates, and being aware of these distinctions ensures a trouble-free laundry experience.

Choosing the Right Option

Selecting between an agitator and a wash plate can be daunting. This section acts as a guide, considering factors such as laundry habits, fabric types, and personal preferences to help consumers make an informed decision.

The choice between an agitator and a wash plate ultimately boils down to personal preference and priorities. GE’s commitment to providing options that cater to various needs ensures that consumers can find the perfect fit for their laundry routine.

Drain Pump in GE Washing Machine: Critical for Water Egress

The GE washer drain pump is a crucial component responsible for expelling water from the machine during the drainage cycle. This process is fundamental to ensure your clothes come out clean and fresh after each wash. The pump operates seamlessly, playing a pivotal role in the overall functionality of the washer.

Signs of a Malfunctioning Drain Pump

Like any mechanical part, the GE washer drain pump is susceptible to wear and tear. Recognizing the signs of a malfunctioning pump is essential to prevent further damage. Slow drainage, unusual sounds during the draining cycle, water leakage around the washer, and error codes on display are indicators that your drain pump may need attention.

Common Causes of Drain Pump Issues

Understanding the root causes of drain pump issues can empower you to address them effectively. Common culprits include accumulation of debris and lint, foreign objects causing blockages, general wear and tear over time, and electrical or mechanical failures.

DIY Troubleshooting for GE Washer Drain Pump

For those who prefer a hands-on approach, there are several DIY troubleshooting steps to consider. From checking for blockages to regular cleaning and maintenance, these actions can often resolve minor issues without professional intervention.

When to Seek Professional Help

However, there are instances when a professional touch is necessary. Signs that DIY solutions are not sufficient include persistent drainage problems and unusual noises. Timely repairs are crucial to avoid further complications, and contacting GE customer support or professional technicians is advisable.

Upgrading Your Washer Drain Pump

If you are in need of a new drain pump, navigating the options available for GE washers can be overwhelming. Considerations such as compatibility, features, and installation processes are crucial when choosing a replacement pump. Upgrading to a more advanced model may enhance the overall efficiency of your washing machine.

Tips for Preventing Drain Pump Issues

Prevention is often the best cure. Establishing regular maintenance routines, using high-quality detergents, and avoiding excessive soap can contribute to the longevity of your drain pump. Additionally, checking and cleaning filters on regularly is a simple yet effective practice.

In conclusion, the GE washer drain pump is a vital component that ensures the smooth operation of your washing machine. Recognizing signs of malfunction, addressing common issues, and staying proactive in maintenance is the key to extending the lifespan of your appliance. As technology evolves, so do the opportunities for improving the performance and efficiency of your GE washer.

Electronics and Controls of GE Washing Machine: The Brain Behind the Operation

GE washing machines transformed from simple appliances to sophisticated pieces of technology. Electronic controls have revolutionized the way we do laundry, providing users with a seamless and efficient experience.

In the not-so-distant past, washing machines relied on mechanical controls. However, as technology progressed, electronic controls found their way into our laundry rooms. GE played a pivotal role in this transition, introducing innovations that paved the way for the modern washing machine.

Key Components

GE washing machine electronics are crucial to comprehending their functionality. From sensors that detect load size to microprocessors that optimize water usage, each component plays a vital role in enhancing the overall performance of the appliance.

Technological Innovations

Recent years have witnessed a surge in technological innovations in washing machine electronics. GE has consistently pushed boundaries, incorporating features that not only improve efficiency but also cater to the ever-changing needs of consumers. Smart connectivity, advanced sensors, and intuitive controls are just a few highlights of GE’s technological prowess.

Common Issues and Troubleshooting

Despite advancements, electronic components can face glitches. This section provides a comprehensive guide to common issues users might encounter and step-by-step troubleshooting tips to resolve them. From error codes to malfunctions, we’ve got you covered.

Maintenance Tips

To ensure the longevity of your GE washing machine electronics, proper maintenance is essential. Learn valuable tips on how to care for electronic components, preventing issues and extending the lifespan of your appliance.

User-Friendly Controls

GE understands the importance of user interface and controls. This section explores the design philosophy behind GE washing machine controls, making laundry a hassle-free experience for users of all ages.

Conclusion

In conclusion, GE washing machine electronics and controls have transformed the laundry experience. From pioneering electronic controls to embracing the latest technological trends, GE continues to be a trailblazer in the industry. As we look to the future, the role of electronics in washing machines is only set to grow, promising even more convenience for consumers.

Suspension and Bearings in GE Washing Machine: Ensuring Smooth Operation

The suspension and bearings in a washing machine are essential components that support the tub and keep it spinning smoothly. Over time, these parts might break down and cause the washing machine to make noise, vibrate excessively and it’s may possible that washer stops working.

Sometime, it may become necessary to replace the bearings or suspension in the washing machine when you are having issues with them. Here are some signs of your suspension or bearings may be worn:

- The washing machine is making a loud noise.

- The washing machine is vibrating excessively.

- The washing machine is not spinning smoothly.

- The washing machine is leaking water.

If you notice any of the above signs, it is necessory to service your washing machine by a qualified technician. They can diagnose the problem and recommend the best solution of your problem.

Here are some tips for extending the life of your washing machine’s suspension and bearings:

- Avoid overloading the washing machine.

- Use the correct cycle for the type of load you are washing.

- Clean the washing machine regularly.

- Have serviced the washing machine by a qualified technician every year.

By following these tips, you can help your washing machine keep running smoothly for many years to come.

The Tub and Drum of GE Washing Machine: Where the Magic Happens

The tub houses the washing drum and is the centerpiece of the washing activity. It’s designed to withstand extreme conditions — water pressure, heavy load, and the chemical action of detergents.

GE washing machine drums are made of either plastic, porcelain-coated steel, or stainless steel. Plastic drums are less prone to erosion, but steel drums are more durable and gentle on clothes.

GE washing machine tubs are moreover horizontal or vertical. Vertical tubs are common in top- load washers, while vertical tubs are common in front- load washers. Horizontal tubs use lower water and energy while Vertical tubs are easier to load and discharge.

GE washing machine drums come in different sizes, ranging from 2.8 to 5.2 cubic feet. The ideal drum size for a washing machine depends on your laundry load size. Generally, larger drums can handle more clothes and big particulars, but lower cans are more effective and suitable for delicate fabrics.

GE washing machine drums have different features, like diamond drum, impeller, or agitator. Diamond drum is a type of steel drum that has diamond- shaped holes to avoid fabric damage. Impeller is a type of plastic drum that has a low- profile cone at the bottom to produce water currents. Agitator is a type of plastic and steel drum that has a central post that moves back and forth to scrub the clothes. Diamond drum and impeller are more gentle and commodious, but Agitator is more effective and powerful.

GE washing machine tub and drum performance very depending on the material, exposure, size, and features of the drum. You can choose the stylish option for your requirements and preferences by comparing the pros and cons of each type

Maintenance and Replacement: Keeping Your Washer in Top Condition

Regular maintenance can prevent disproportionate wear and tear on your GE washer, which is crucial to avoid bigger issues down the line. However, parts do wear out and break. Knowing when and what to replace is important to maintain the machine’s lifespan.

Conclusion: Why Quality Parts Matter

In the realm of appliances, few things are as frustrating as a malfunctioning washing machine. It’s not simply about the inconvenience, but also about the potential water damage, the disruption to your routine, and the costs associated with repairs. High-quality GE washing machine parts are the antidote to common laundry woes; they are specifically designed to enhance the performance of your washer and extend its lifespan.

By understanding the critical components of your GE washing machine and how they operate in unison, you can better appreciate the ingenuity behind each cycle. Regular maintenance and timely replacement of these parts ensure that your washing experiences remain seamless. For those looking to delve deeper into the specifics of GE washing machine components, there are resources available to guide you through troubleshooting and selecting the right parts for your machine.

In essence, the reliability of your GE washing machine relies heavily on the integrity of its parts. Securing genuine, high-quality replacements will safeguard its performance, providing peace of mind and spotless laundry for years to come.

I like the helpful info you supply to your articles. I’ll bookmark your blog and check once more here regularly. I’m reasonably sure I will be told a lot of new stuff right here! Best of luck for the next!

Dear Alberto D. Harris,

Thank you so much for your kind words! We’re delighted to hear that you find our articles helpful and informative. We’re also thrilled that you’ve decided to bookmark our blog and check back regularly. We’re always striving to provide valuable and engaging content for our readers, and your positive feedback means a lot to us.

Sincerely,

Team THEMACHINEMASTERS